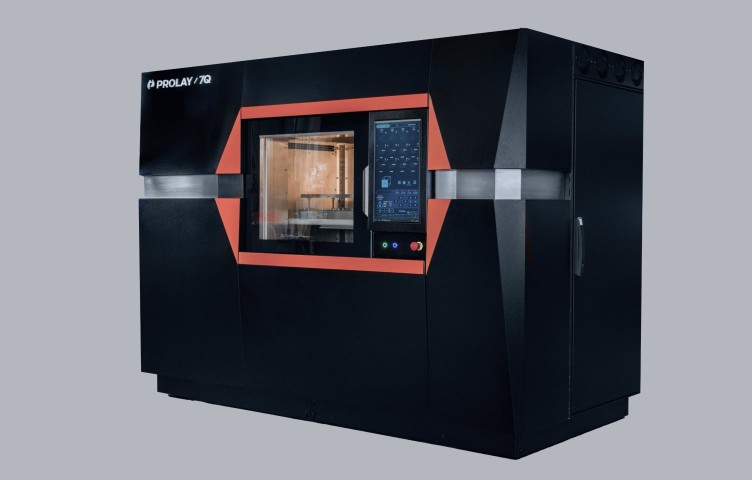

Prolay - Next Level of Additive Manufacturing

Prolay - Next Level of Additive Manufacturing

Explore our revolutionary 3D printing solution, which is designed to be innovative and more advantageous technology on the market and overcome all limitations.

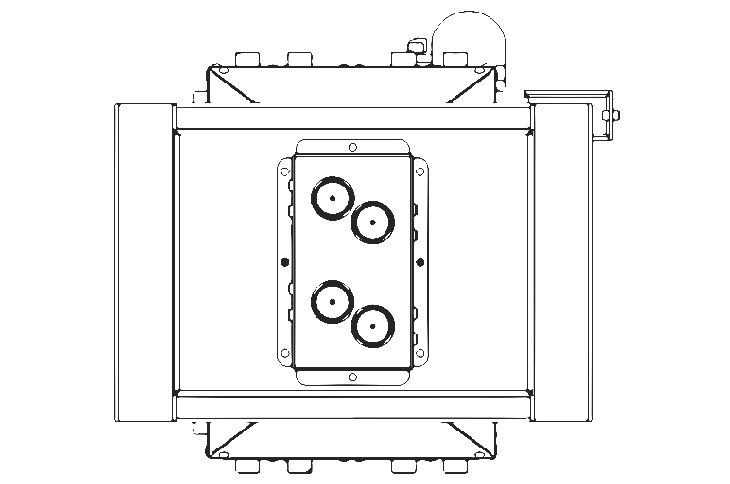

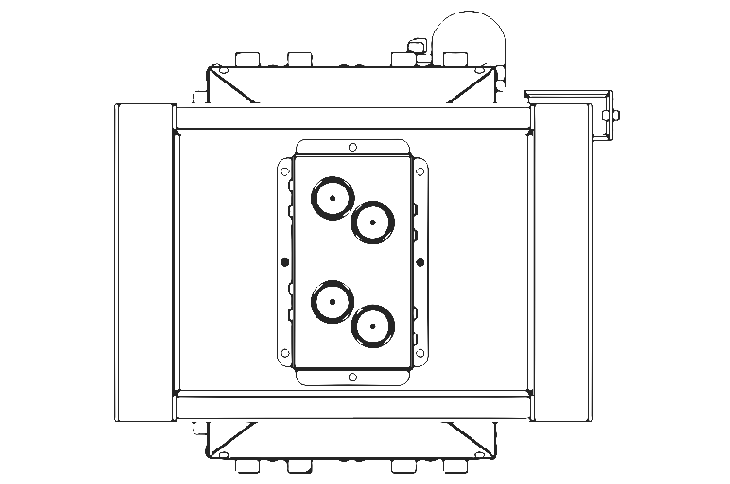

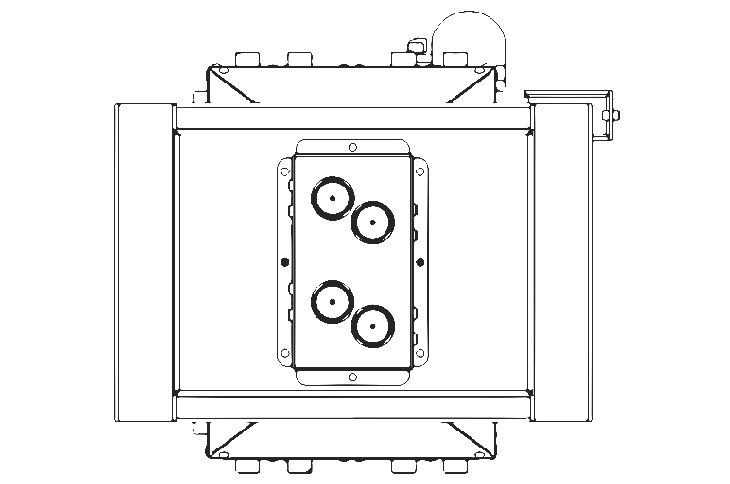

With speed and precise detail resolution, our printer offers phenomenal possibilities. Equipped with four extrusion heads with different nozzle diameters and the ability to mix multiple materials, it allows for outstanding flexibility. Experience faster progressive production without losing quality.

Prolay - Next Level of Additive Manufacturing

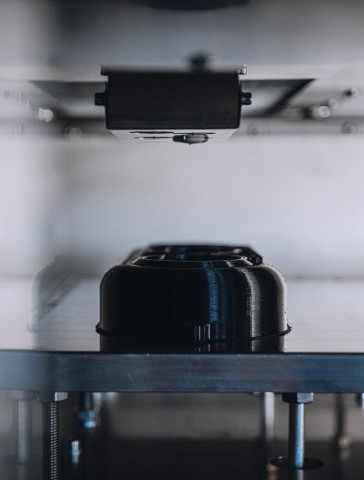

0,1 mm detail resolution

Precise outer wall and fast rough core in a single process

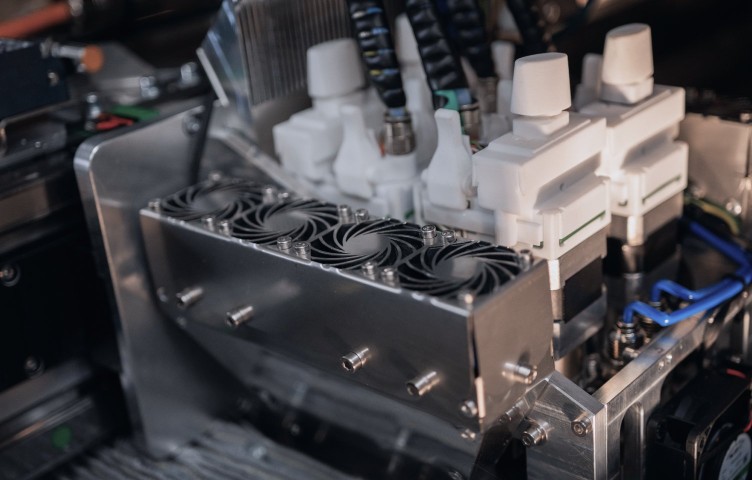

4 extruder head

With 4 different nozzle diameters from 0,25 mm up to 1 mm

Up to 5 times faster

1,5 to 5 times faster depending on the geometry

Even 800 g/h throughput

Progressive layer thickness allows higher extrusion speed

Strong composites

Mix up to 3 different materials in one single process

Prolay - Next Level of Additive Manufacturing

Release your creativity and discover unlimited possibilities with PROLAY.

Prolay - Next Level of Additive Manufacturing

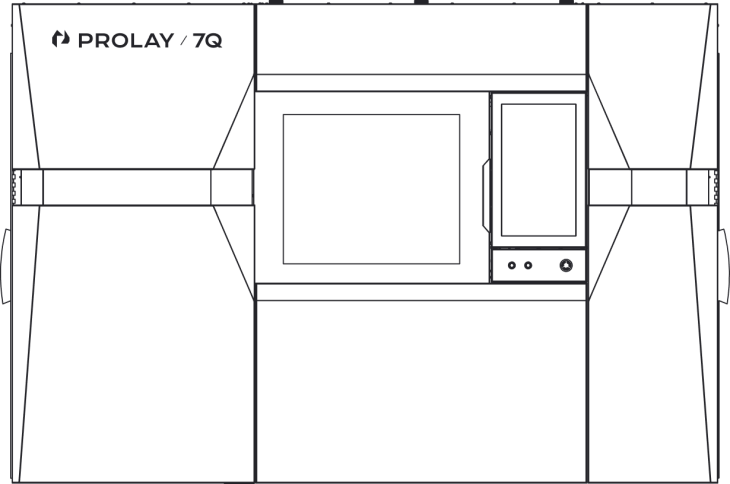

Discover the dedicated software

Unlock full potential of PROLAY with dedicated software, designed to improve your 3D printing experience. Our software unlocks new levels of productivity and precision, enabling you to achieve outstanding results.

Streamline your production process and maximize efficiency with intuitive navigation and advanced features. From design to final part, PROLAY software provides a smooth workflow, enabling you to create complex and accurate 3D printed parts.

Explore the future of 3D printing with dedicated PROLAY software. Take your designs to a new level today.

Prolay - Next Level of Additive Manufacturing

Web-based Software

Enjoy the convenience of our web-based software, accessing and managing your 3D printing projects anytime, anywhere.

Three account levels

Choose from beginner, intermediate or advanced levels to match your AM experience.

Predefined Parameter Sets

Simplify your printing process with our software's predefined parameter sets for various materials.

Open Parameters Database

Unlock customization and experimentation with our software's open database of process parameters.

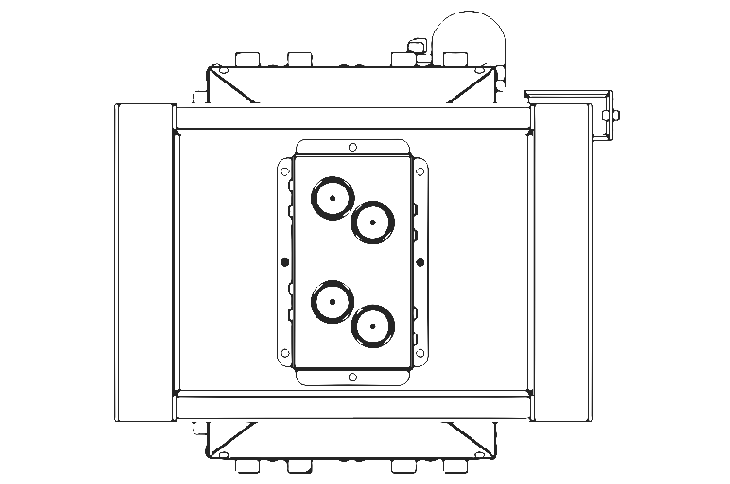

Specifications

3D printing parameters

3D printing technology

PLTM (Progressive Layer Thickness Manufacturing)

Build volume

725 x 450 x 500 [mm]

Chamber temperature

Up to 190 [°C]

Number of printheads with tip diameter

4 printheads, 0,2 – 0,6 [mm]

Printhead temperature

Up to 400 [°C]

Layer Height

0,05 to 1,6 [mm]

Linear motors max velocity

Up to 600 [mm/s]

Filaments

ABS, ABS-CF, PC, PC-CF, PC-ABS and others

Physical dimensions, weight and power

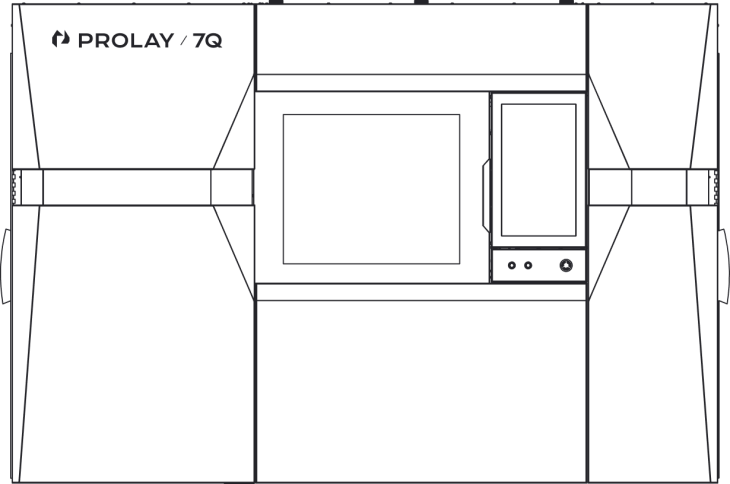

Dimensions

2685 x 1887 x 1334 [mm]

Weight

~1850 [kg]

Power requirements

230 [VAC] (3 phases), 16 [A], max. power consumption 12 [kW]

Compressed air supply

Yes, 6 [bar]

Comunication

WiFi, Ethernet

Software parameters

Software

PROLAY3D

Supported formats

STL

System requirements

Windows, Linux

Compliances

SIL 3, CE, 2006/42/WE

Materials

Prolay - Next Level of Additive Manufacturing

Our approach to manufacturing using the PROLAY 3D printer is to provide our customers the freedom to create parts using a wide range of materials available on the market

The machine construction, versatile extruders, open material platform with the abbility to change over 100 parameters have been design to open up the possibilites of processing a wide range of filamets.

Prolay - Next Level of Additive Manufacturing

High-strength and widely used, ABS is ideal for industrial applications, offering durability and impact resistance. Its excellent dimensional stability makes it suitable for the automotive and aerospace industries, enabling the production of jigs & fixtures and final parts.

Carbon fiber-reinforced ABS provides improved strength and stiffness, making it ideal for applications requiring lightweight but durable components. Industries such as automotive and robotics benefit from the high-performance properties of ABS-CF, enabling the production of structurally rigid parts.

A material with excellent mechanical properties and high heat resistance, making it suitable for applications requiring durability. Industries such as electronics and medical devices use PC for its excellent impact resistance and ability to withstand tough working conditions.

Combining the strength of polycarbonate with carbon fiber reinforcement, PC-CF offers exceptional rigidity and dimensional stability. This material is used in the aerospace, automotive and sports equipment industries, where lightweight components with high strength and heat resistance are needed.

Combines the mechanical properties of polycarbonate and the flexibility of ABS to create a material with excellent impact and heat resistance. It is widely used in the automotive and tooling industries to produce durable, functional prototypes and final parts.