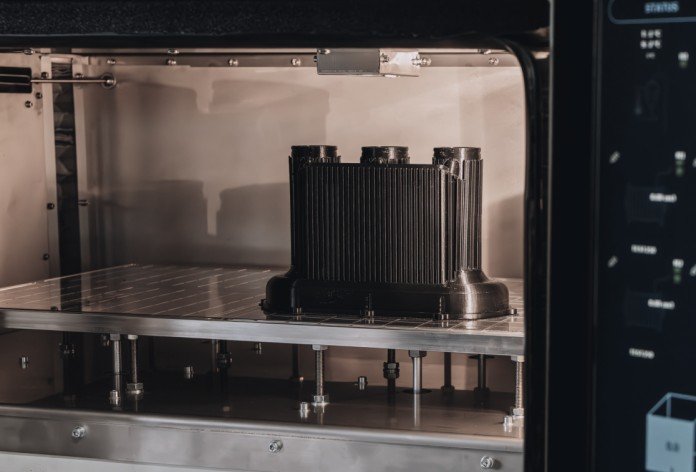

PLTM (Progressive Layer Thickness Manufacturing) is a manufacturing technology that enables you to build your parts by progressively adding layers by layer of melted filament over the build plate.

Prolay - Next Level of Additive Manufacturing

PROLAY and PLTM Technology were developed in response to the limitations that many additive manufacturing technologies on the market have always faced.

Our broad experience in working with advanced led to the idea of breaking through these barriers, opening up new paths for development and unlocking new creative possibilities with improved machine efficiency. The result is an open system that allows unlimited projects, combined with significant productivity enhancements. Experience the freedom to innovate and reach higher levels of productivity with our cutting-edge solution.

Prolay - Next Level of Additive Manufacturing

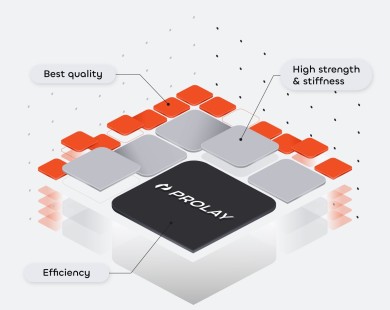

High strength and stiffness

Unrivaled Strength: Say goodbye to compromise.

Our high-strength solution powered by our PLTM technology provides parts that ensures exceptional durability and structural integrity without the loss of quality. Overlapping internal progressive layers ensure that the stiffness capabilities of produce parts meet or exceed the requirements of traditional manufacturing processes. Whether you're building components for industrial machinery or functional prototypes, rest assured that your prints will endure rigorous usage and demanding environments.

Best quality

Introducing the Next Level of Precision without printing time compromise.

Unlock new possibilities and redefine your expectations towards 3D printing surface quality with our cutting-edge PLTM 3D printing technology. Achieve premium results without sacrificing efficiency. Our PLTM solution optimizes production time and material usage, ensuring you get exceptional quality at an affordable cost regardless of the size of your part.

Efficiency

Lightning-Fast Speed: Surpass expectations with our new PLTM exceptional printing speed.

We've pushed the boundaries of technology to deliver rapid print times without compromising on quality and durability. Say goodbye to long waiting periods and hello to accelerated production cycles, allowing you to complete projects in record time. Whether you're a professional seeking streamlined production or an enthusiast eager to bring your ideas to life rapidly, our technology is your ultimate tool.

Prolay - Next Level of Additive Manufacturing

Explore new horizons with PROLAY and PLTM Technology today.

Vision & Solution video

PLTM vs FDM

Introducing the Next Level of Additive Manufactiring

Classic approach

High-Quality Surface without time and material strength compromise – the PLTM technology.

A game-changing advancement that redefines the boundaries of what’s possible and enables you to print your parts 2 – 5 times faster than the competition with the surface quality of 0,1 mm layer and superb material properties powered by composite materials.

PLTM approach

High-Quality Surface without time and material strength compromise – the PLTM technology.

A game-changing advancement that redefines the boundaries of what’s possible and enables you to print your parts 2 – 5 times faster than the competition with the surface quality of 0,1 mm layer and superb material properties powered by composite materials.

How does PLTM works?

A typical 3D printer works by deposing or sintering a layer of material over a build platform layer by layer until the part is completed.