Additive manufacturing, also known as 3D printing, has become an integral part of industrial processes. With its ability to produce complex geometries and functional parts with high precision, 3D printing has revolutionized the way we manufacture.

In today's dynamic market landscape, the demand for flexible and customized manufacturing solutions is on the rise. 3D printing offers the agility to produce on-demand, enabling businesses to quickly respond to changing customer needs and tailor parts to specific requirements. This competitive advantage allows companies to stay ahead in a rapidly evolving market and deliver unique solutions to their customers. Additionally, localized production through 3D printing reduces supply chain dependencies and mitigates risks associated with long-distance transportation, ensuring faster delivery times and increased supply chain stability. As the demand for additive manufacturing continues to grow, companies are seeking more efficient methods to optimize their production processes and overcome the limitations of traditional 3D printing technologies.

The Limitations of Traditional 3D Printing Technologies

While traditional 3D printing has revolutionized the manufacturing landscape, it still faces certain limitations that can hinder its widespread adoption for industrial applications. One of the major challenges is achieving parts with excellent surface quality and high strength in a short time. Traditional methods often require a trade-off between surface finish and production speed, which can limit the full potential of additive manufacturing.

Introducing Progressive Layer Thickness Manufacturing

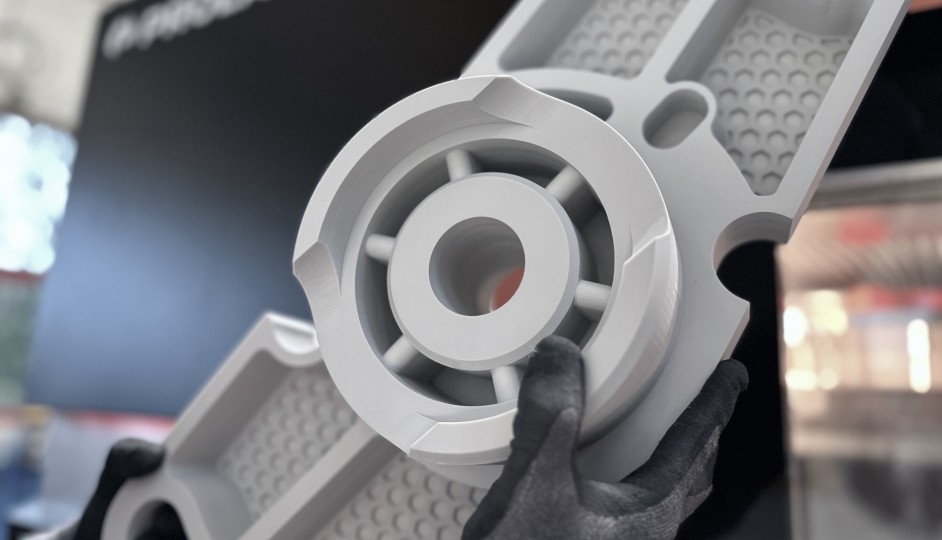

In response to these challenges, Progressive Layer Thickness Manufacturing (PLTM) technology has emerged as a game-changing advancement in additive manufacturing. Unlike conventional methods, PLTM begins with a unique software that automatically slices the designed part into groups with different layer thicknesses. Each group can specific material profile and a set of individual parameters, allowing for precise control over the printing process. PLTM solution is based on a multi-head material deposition approach. Each printing head is equipped with a specific nozzle diameter, allowing for easy application of layers with varying thicknesses to the printed part. The process begins by depositing the outer layer of material with the finest layer resolution and gradually increases the layer thickness and width within the part. This progressive approach ensures exceptional surface quality and high durability in the final product. Moreover, it significantly enhances the speed of additive manufacturing. With PLTM technology, you can achieve precise control over the printing process, producing parts with outstanding quality and strength while optimizing production efficiency.

Next Level of Additive Manufacturing: High-Quality Surface without Time and Material Compromises

The PLTM Technology powered by PROLAY, represents a huge step forward in additive manufacturing. It allows for producing parts 2-5 times faster than traditional 3D printing methods while maintaining high surface quality and durability. With the capability to use four printing heads, it enables combining different filaments, including composite materials, in a single process. This opens up new possibilities for creating parts with exceptional strength and durability, as well as unique material properties. Implementing the PLTM Technology enables manufacturers to optimize their workflows, enhance production standards, and achieve significant time and cost savings. It's a game-changer that revolutionizes additive manufacturing, offering remarkable speed, quality, and flexibility.

Advantages of PLTM Technology

Adopting PLTM technology offers a multitude of advantages that positively impact the manufacturing landscape:

- Reduced Production Time: By accelerating the production cycles, PLTM technology reduces energy consumption, resulting in cost savings and increased productivity. This enables companies to meet growing demands while remaining competitive in the market.

- Accelerated Innovation: Incorporating PLTM as an integral part of the manufacturing workflow opens doors to rapid innovation. Companies can quickly iterate designs, introduce new products, and bring concepts to market faster than ever before, gaining a crucial competitive edge.

- Enhanced Manufacturing Standards: With PLTM, companies can optimize their manufacturing processes, improve production standards, and stay ahead of the competition. The ability to create parts with exceptional surface quality and strength empowers businesses to deliver products that meet the highest industry standards.

- Limitless Creativity: PLTM technology enables manufacturers to push the boundaries of what is possible. With the power of limitless creativity at their disposal, companies can explore uncharted territories in design and manufacturing, unleashing their full potential for innovation.

Conclusion

As additive manufacturing continues to revolutionize the industrial landscape, PLTM technology emerges as a pivotal advancement that propels the industry forward. By implementing PLTM, companies can take control of their production environment, optimize their workflows, and unlock new opportunities for growth and success. With its ability to overcome traditional manufacturing limitations and produce parts with superior strength, durability, and surface quality, PLTM is set to redefine the possibilities of additive manufacturing.

To learn more about how PLTM technology can transform your manufacturing operations and unleash the full potential of additive manufacturing, contact us today. Discover how you can leverage this groundbreaking technology to stay at the forefront of industry innovation and gain a competitive edge. Embrace the future of manufacturing with PLTM and embark on a transformative journey that redefines the boundaries of what's possible.