From November 7-10, Frankfurt again became a center for innovation and additive manufacturing, hosting the Formnext 2023 event. This renowned event, which has consistently pushed the boundaries of manufacturing technology, witnessed an impressive turnout of nearly 33,000 visitors. Featuring 859 exhibitors from across the globe, representing 59% of the participants from outside Germany, the event showcased the expansive and evolving landscape of additive manufacturing, spanning diverse sectors like medical technology, automotive, mechanical engineering, and more.

PROLAY aligns with the current manufacturing trends

This years Formnext focused on improving productivity through innovative additive manufacturing solutions, a trend that has become more important in the current economic climate. Amidst this backdrop of groundbreaking advancements, PROLAY proudly presented a solution that aligns perfectly with the industrys trajectory towards more efficient and productive manufacturing methods.

In the current economic landscape, the urgency to elevate productivity and shorten production timelines is more pronounced than ever before. PROLAYs innovative approach, which uses Progressive Layer Thickness Manufacturing (PLTM) technology, meets these critical needs well. Our debut at Formnext provided us with the opportunity to demonstrate how our solutions significantly contribute to the evolving additive manufacturing industry.

A key highlight of our presentation was the advantages of PLTM technology. This technology has the potential to revolutionize the manufacturing process by enabling the production of parts with varying layer thicknesses within the same object, thereby enhancing strength, quality, and speed. This approach aligns with the industrys drive towards enhanced productivity and presents novel avenues for customization and creative freedom in design.

The requirement for advanced materials

At Formnext 2023, it became clear that there is a growing demand for advanced engineering materials in the additive manufacturing industry. The focus was on industrial applications that utilize engineered plastics, specifically carbon fiber-reinforced composites and high-temperature materials such as ULTEM and PEI. These materials are increasingly sought after due to their superior attributes, including enhanced strength, durability, and thermal stability, rendering them ideal for demanding industrial applications.

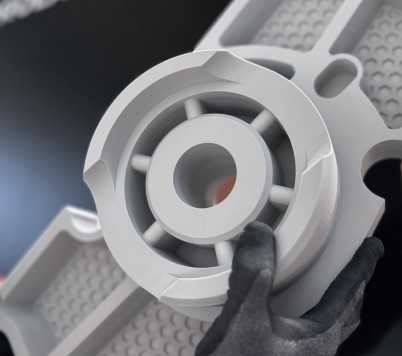

PROLAY 7Q solution fits the new trends perfectly. The components we showcased, which were manufactured with our advanced Progressive Layer Thickness Manufacturing (PLTM) technology, received a favorable reception, highlighting the industry's enthusiasm for novel material applications. The 7Q ability to handle complex materials demonstrated our commitment to meeting industry's growing demands for high-performance, durable, and versatile components.

Furthermore, the PROLAY 7Q unique ability to combine up to three different materials in one process sets a new standard in the creation of composite structures. This feature is not merely an advancement; it represents a revolutionary change in the manufacturing industry, thereby opening up a broader range of applications. The use of multiple materials allows for the design of parts that combine the best attributes of each material, from the rigidity of carbon fiber to the heat resistance of ULTEM. This combination leads to the production of parts that were once thought impossible, opening the way for new solutions in different areas.

Our participation in Formnext 2023 not only strengthened PROLAY position as a leader in advanced manufacturing solutions but also highlighted the industry's readiness to embrace such transformative technologies. As we move forward, PROLAY is excited to working with companies looking to explore the full potential of advanced engineering materials, enhancing their manufacturing capabilities to meet the demands of today's challenging economic environment.

Thank you from the PROLAY team for inspiring Formnext

Our participation at Formnext 2023 was met with great interest and enthusiasm, demonstrating the industrys readiness for such innovative advancements. This response has further strengthened our commitment to optimizing manufacturing processes and offering solutions that redefine traditional manufacturing.

As we reflect on the successful week at Formnext 2023, we express our gratitude to all the organizers, exhibitors, and visitors who have contributed to this dynamic exchange of ideas and expertise. We're looking forward to the future, and we'd like to help companies find cutting-edge manufacturing solutions by exploring the possibilities offered by PROLAY. Our technology is not just about keeping up with industry trends; it’s about making manufacturing more efficient and productive.

We look forward to next years event and the continued growth of the additive manufacturing industry. Let’s embark on a journey to redefine manufacturing strategies and embrace the future of additive manufacturing.

See you at Formnext 2024, where manufacturing meets innovation!